Unbelievable Tips About Why The PWM Is Used

Demystifying PWM

1. Understanding the Basics of Pulse Width Modulation

Ever wondered how devices smoothly dim lights, control motor speeds, or generate different audio tones? Chances are, Pulse Width Modulation, or PWM for short, is the magic behind the curtain. PWM isn't some obscure, highly technical concept reserved for engineers in white coats. In fact, it's a clever and efficient technique that's deeply ingrained in many aspects of our modern lives. But what is it, exactly? Well, at its core, PWM is a way of controlling the amount of power delivered to an electrical device by switching the power on and off very quickly. Think of it like flicking a light switch really, really fast.

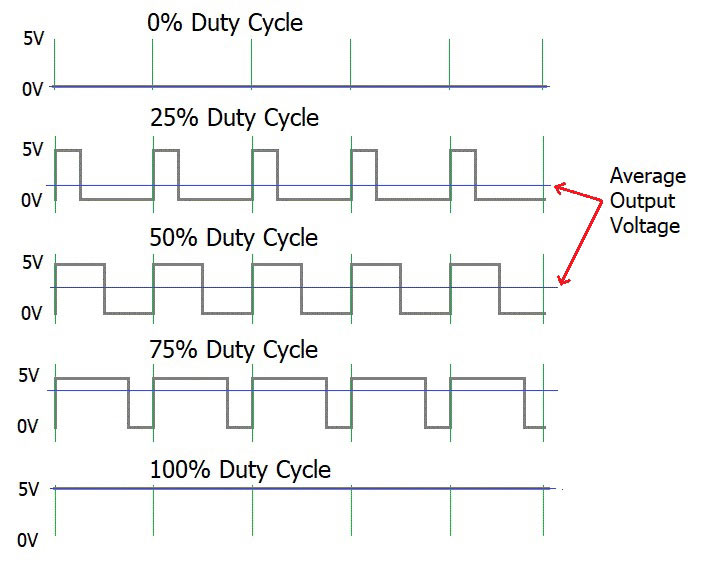

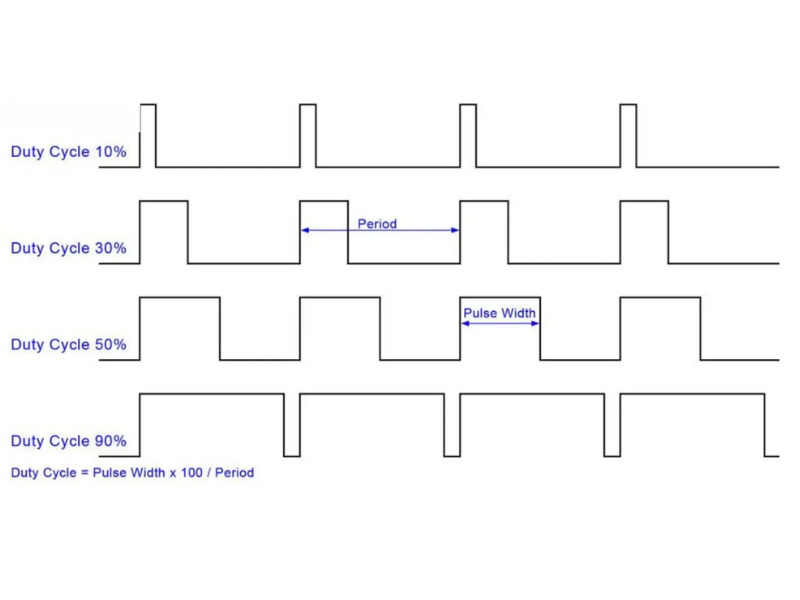

Instead of adjusting the voltage or current directly, which can be inefficient and generate heat, PWM varies the duty cycle. The duty cycle is simply the percentage of time the power is "on" compared to the total cycle time. A 50% duty cycle means the power is on for half the cycle and off for the other half. A 10% duty cycle? The power is on for a tiny sliver of time, and off for the vast majority. And a 90% duty cycle? You guessed it, nearly all the time! By carefully controlling this duty cycle, we can effectively simulate different voltage levels, even though the actual voltage is either fully on or fully off. It's a bit like creating a smooth gradient with tiny, discrete steps— the steps are so small that our perception blends them together into a seamless whole.

Now, you might be thinking, "Why not just use a dimmer switch that directly reduces the voltage?" That's a valid question! While dimmer switches work, they often dissipate a lot of energy as heat, making them less efficient. PWM, on the other hand, uses transistors as switches, which are either fully on (conducting with very little resistance) or fully off (blocking current completely). This dramatically reduces energy loss in the form of heat. Plus, PWM offers much finer control and can be easily implemented with microcontrollers and digital circuits, making it incredibly versatile.

So, PWM is basically a super-efficient way to control power by rapidly switching it on and off, varying the amount of time the power is "on" (the duty cycle). This allows us to create smooth, variable control of various devices, all while minimizing energy waste and maximizing flexibility. It's a deceptively simple concept with surprisingly powerful applications!

Penerapan Pulse Width Modulation Pwm Pada Arduino Dunia Elektro Vrogue

Efficiency is Key

2. The Power-Saving Prowess of PWM

One of the biggest reasons PWM is so widely used is its remarkable efficiency. Traditional methods of controlling power, like linear voltage regulators, tend to waste a significant amount of energy as heat. Imagine trying to control the speed of a fan by simply resisting the flow of electricity — that resistance generates heat, which is just wasted energy. PWM elegantly avoids this problem by acting as a switch. When the switch is on, electricity flows freely with minimal resistance; when the switch is off, no electricity flows at all. This "on-off" action minimizes energy loss, making PWM a much more efficient solution.

Think about it this way: if you want to dim a lightbulb, a traditional dimmer switch essentially converts some of the electrical energy into heat. You're paying for that electricity, but it's not contributing to the light output. With PWM, the lightbulb is either fully on or fully off, but the rapid switching creates the illusion of dimming. Because the transistor (the switch) is either fully on or fully off, very little energy is lost as heat. This translates to significant energy savings, especially in applications where power control is constantly needed.

This efficiency is particularly crucial in battery-powered devices like smartphones, laptops, and electric vehicles. In these applications, every milliwatt of energy saved translates to longer battery life. By using PWM to control motor speeds, screen brightness, and other functions, these devices can squeeze every last drop of power from their batteries, extending usage time and reducing the frequency of recharging. PWM's efficiency is not just about saving money on electricity bills; it's about making our devices more portable, convenient, and environmentally friendly.

So, when you're considering why PWM is so popular, always remember its exceptional efficiency. By minimizing energy waste and maximizing power utilization, PWM helps us save energy, extend battery life, and create a more sustainable future. It's a win-win situation!

Digital Control Solution For 3level Inverters Renesas

Versatility Unleashed

3. From Dimming Lights to Controlling Motors

PWM isn't just a one-trick pony; its versatility is another major reason for its widespread adoption. This clever technique can be used in a surprising range of applications, from the mundane to the cutting-edge. One of the most common uses of PWM is in controlling the brightness of LEDs. By adjusting the duty cycle, we can precisely control the amount of light emitted, creating a smooth dimming effect. This is used in everything from smartphone screens to stage lighting.

Another area where PWM excels is motor control. By varying the duty cycle, we can precisely regulate the speed of a DC motor. This is essential in countless applications, including robotics, electric vehicles, and even simple household appliances like fans and power tools. PWM allows for smooth, precise control of motor speed, making it ideal for applications that require fine-tuning and responsiveness.

Beyond lighting and motor control, PWM is also used in audio amplifiers to create efficient Class-D amplifiers. These amplifiers use PWM to switch the output transistors on and off, minimizing power loss and improving efficiency compared to traditional linear amplifiers. PWM is also used in power supplies to regulate voltage and current, and in solar charge controllers to optimize the charging of batteries. The ability to precisely control power delivery makes PWM a valuable tool in a wide variety of electrical and electronic systems.

It's this adaptability that truly sets PWM apart. Whether you need to dim a light, control a motor, generate audio, or regulate power, PWM offers a flexible and efficient solution. Its ability to be implemented with microcontrollers and digital circuits makes it easy to integrate into a wide range of designs, further contributing to its popularity and widespread use.

Simplicity and Cost-Effectiveness

4. Easy Implementation and Reduced Costs

While PWM might sound complicated, the underlying principle is relatively simple, and implementing it is surprisingly cost-effective. This simplicity and affordability are key factors in its widespread adoption. PWM can be easily implemented using microcontrollers, which are readily available and relatively inexpensive. These microcontrollers can be programmed to generate PWM signals with precise control over the duty cycle and frequency.

Compared to other methods of power control, PWM requires fewer components and less complex circuitry. This reduces the overall cost of the system and simplifies the design process. The use of transistors as switches, rather than more complex and expensive linear regulators, further contributes to the cost-effectiveness of PWM. In mass-produced devices, even small cost savings can add up to significant amounts, making PWM a particularly attractive option.

The ease of integration with microcontrollers also means that PWM can be easily adapted to different applications and adjusted to meet specific requirements. This flexibility reduces development time and allows for rapid prototyping. Engineers can quickly experiment with different PWM parameters to optimize performance and efficiency for their particular application. This adaptability and ease of use make PWM a valuable tool for both experienced engineers and hobbyists alike.

In short, the combination of simplicity, affordability, and ease of integration makes PWM a highly attractive option for a wide range of power control applications. Its cost-effectiveness, coupled with its efficiency and versatility, has cemented its place as a fundamental technique in modern electronics.

Pengertian PWM (Pulse Width Modulation) Fungsi Dan Cara Kerja

PWM in the Future

5. The Evolving Landscape of Pulse Width Modulation

Even though PWM has been around for quite some time, it's far from a stagnant technology. Research and development are constantly pushing the boundaries of what's possible with PWM, leading to new and innovative applications. One area of active research is advanced PWM techniques, such as space vector modulation, which can improve the efficiency and performance of motor drives. These techniques are becoming increasingly important in applications like electric vehicles and industrial automation, where high efficiency and precise control are paramount.

Another area of focus is the integration of PWM with digital signal processing (DSP) and artificial intelligence (AI). By using DSP algorithms to optimize PWM parameters in real-time, we can achieve even greater efficiency and performance. AI can also be used to learn the optimal PWM settings for different operating conditions, further improving the overall system performance. This integration of PWM with advanced control techniques promises to unlock even greater potential in a wide range of applications.

Furthermore, as power electronics continue to shrink in size and increase in efficiency, PWM will play an increasingly important role in miniaturized devices and portable electronics. The ability to precisely control power in a small form factor is essential for the development of new generations of smartphones, wearables, and other portable devices. PWM's efficiency and versatility make it an ideal choice for these applications.

In conclusion, PWM is not just a technology of the past; it's a technology of the future. Continued innovation in PWM techniques, coupled with advancements in digital signal processing and artificial intelligence, will ensure that PWM remains a vital and indispensable tool in the field of power electronics for years to come. The ongoing research and development in this area promise to unlock even greater potential and expand the range of applications for this versatile and efficient technology. So, keep an eye on PWM—it's sure to continue shaping the world around us.

Frequently Asked Questions (FAQs)

6. Your PWM Questions Answered!

We've covered a lot about PWM, but you might still have some questions. Here are a few common ones:

Q: What's the difference between PWM and analog control?A: Analog control directly adjusts the voltage or current, which can be inefficient. PWM, on the other hand, switches the power on and off rapidly, varying the duty cycle to simulate different voltage levels. This is generally more efficient and easier to control with digital circuits.

Q: Can PWM damage my devices?A: When implemented correctly, PWM is perfectly safe. The switching frequency is usually high enough that the device being controlled doesn't experience any negative effects. However, poorly designed PWM circuits can sometimes cause issues, so it's important to use proper engineering practices.

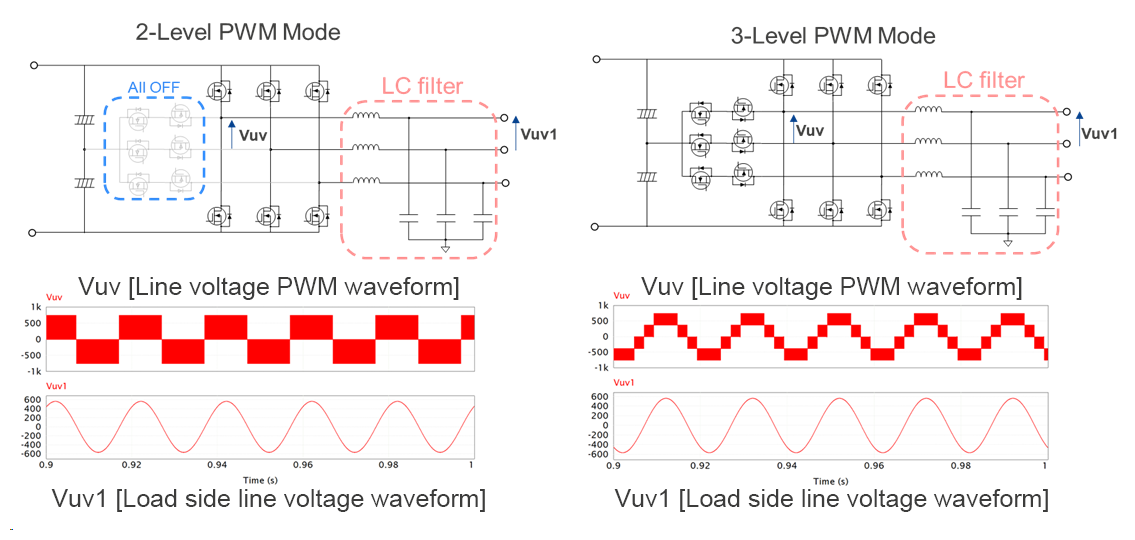

Q: Is PWM only used for DC devices?A: While PWM is commonly used with DC devices like LEDs and motors, it can also be used with AC devices in certain applications, such as inverters. In these cases, the PWM signal is used to control the switching of transistors to generate an AC waveform.

Q: What determines the ideal PWM frequency?A: The best PWM frequency depends on the specific application. Too low, and you might hear or see flickering; too high, and switching losses in the transistor can become significant. You need to strike a balance that is inaudible/invisible, and efficient.