Wonderful Info About How Many Motors Can L293D Control

Decoding the L293D

1. Understanding the L293D Motor Driver IC

So, you're tinkering with robotics, maybe building a cool little remote-controlled car, or perhaps a miniature automated factory? Excellent! Chances are, you've stumbled upon the L293D, a handy little integrated circuit (IC) often called a motor driver. But before you get too excited and start wiring up every motor you own, let's address the burning question: just how many motors can this thing actually wrangle? The answer, as with many things in electronics, isn't quite as straightforward as a simple number.

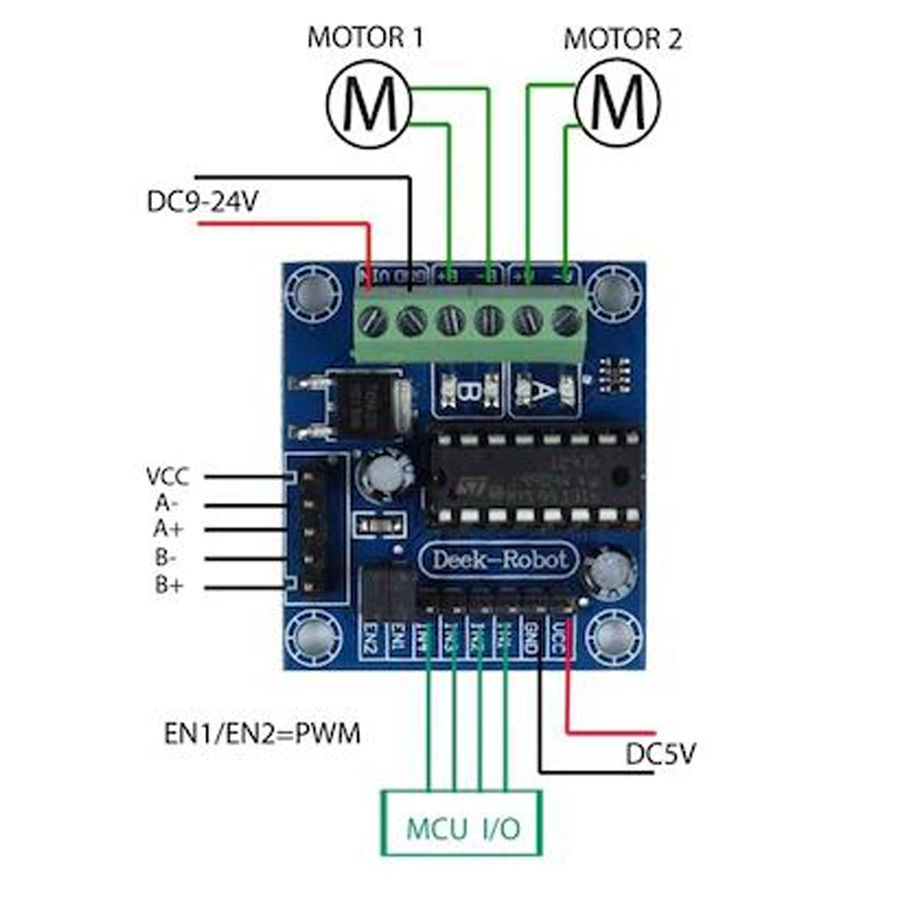

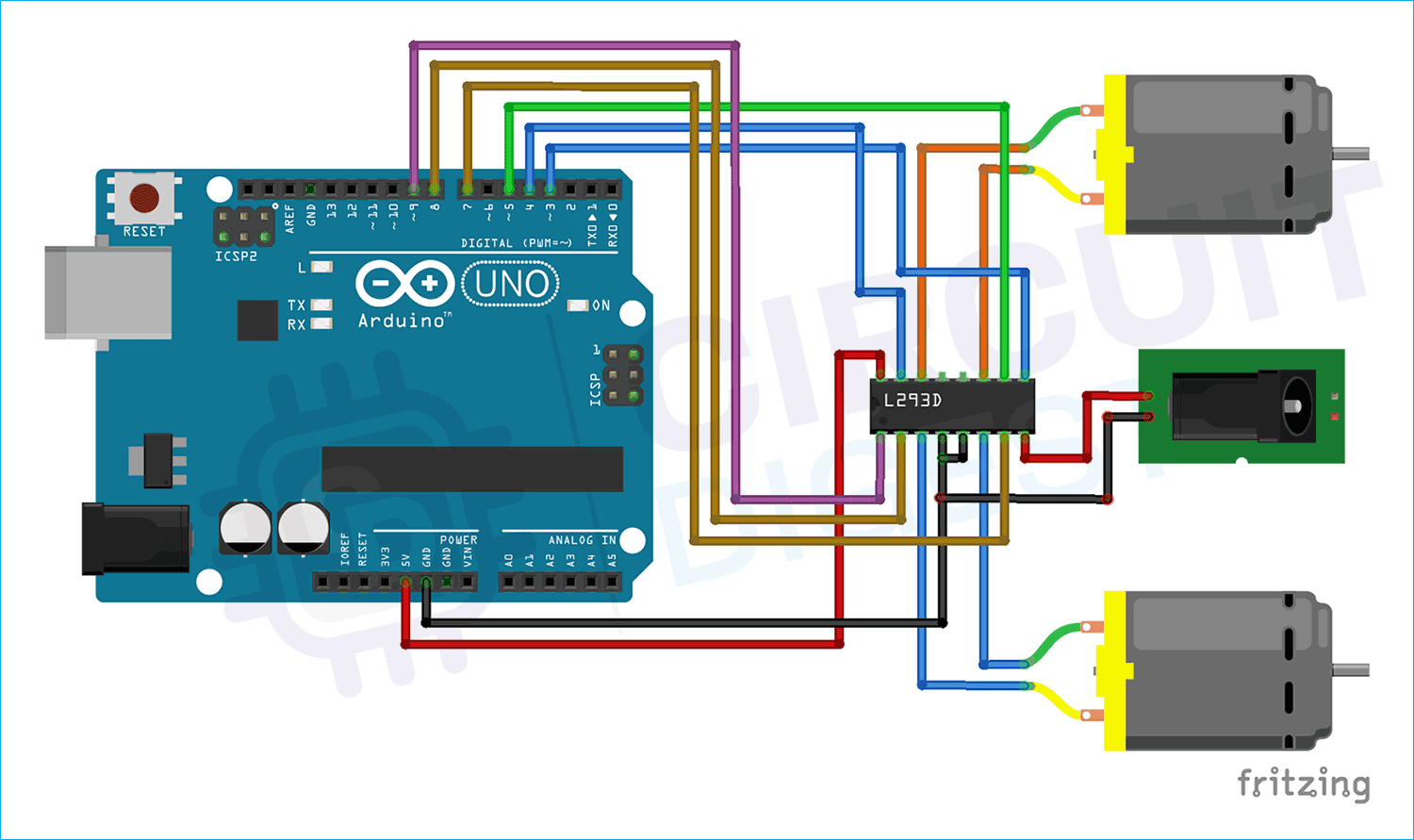

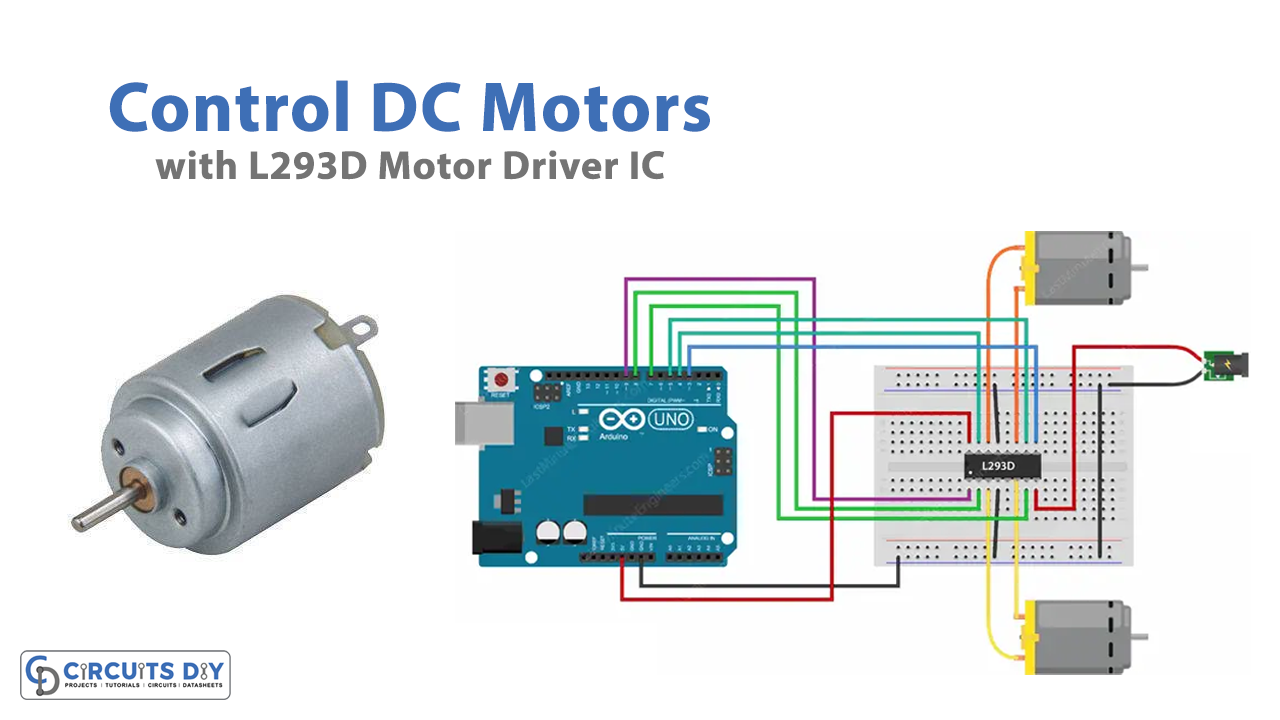

The L293D is essentially a dual H-bridge driver. Think of an H-bridge like a tiny, electronic traffic controller for each motor. It allows you to control the direction and speed of a DC motor by managing the flow of current. Because the L293D is a "dual" driver, it means it has two of these H-bridges packed inside. Each H-bridge can independently control one DC motor. Therefore, at its core, the L293D is designed to drive two DC motors. Plain and simple? Maybe not, we'll get into it later.

However, there are a few caveats to consider. Firstly, the L293D has current limitations. It can provide up to 600mA (0.6 Amps) per channel (per H-bridge) continuously, with a peak current of around 1.2A. If your motors require more current than that, the L293D will overheat and potentially be damaged — a sad day for your project and your wallet! So, before you even think about the number of motors, check their current draw at the voltage you plan to use. The motors' datasheet should clearly provide these specifics.

Another factor is voltage. The L293D can operate with motor supply voltages up to 36V. Again, ensure your motors fall within this range. Trying to push more voltage than the L293D is rated for is a recipe for electronic disaster. Also, it's important to have adequate heat sinking or cooling when you're pushing the L293D near its maximum ratings, especially if it's in an enclosed space. A small heatsink can significantly improve its lifespan.

Control DC Motors With Arduino And L293D Motor Driver IC

Beyond Two

2. Thinking Outside the (Two Motor) Box

While the L293D is designed to drive two DC motors independently, there are ways to get a little more creative. One approach involves connecting motors in parallel to a single channel of the L293D. This is generally only advisable if you're dealing with very small, low-current motors, and you need them to run in sync (i.e., at the same speed and in the same direction). You have to ensure that the combined current draw of the motors in parallel stays well within the 600mA limit of the L293D channel.

The crucial point here is that parallel connections require careful consideration. Any imbalance in the motors' characteristics (even slight differences in internal resistance) can lead to uneven current distribution, potentially overloading one motor while starving the other. This could lead to motor damage or unpredictable behavior. In short, parallel connections are possible, but proceed with caution and thorough testing! Always monitor the temperature of the L293D and the motors when experimenting with parallel configurations.

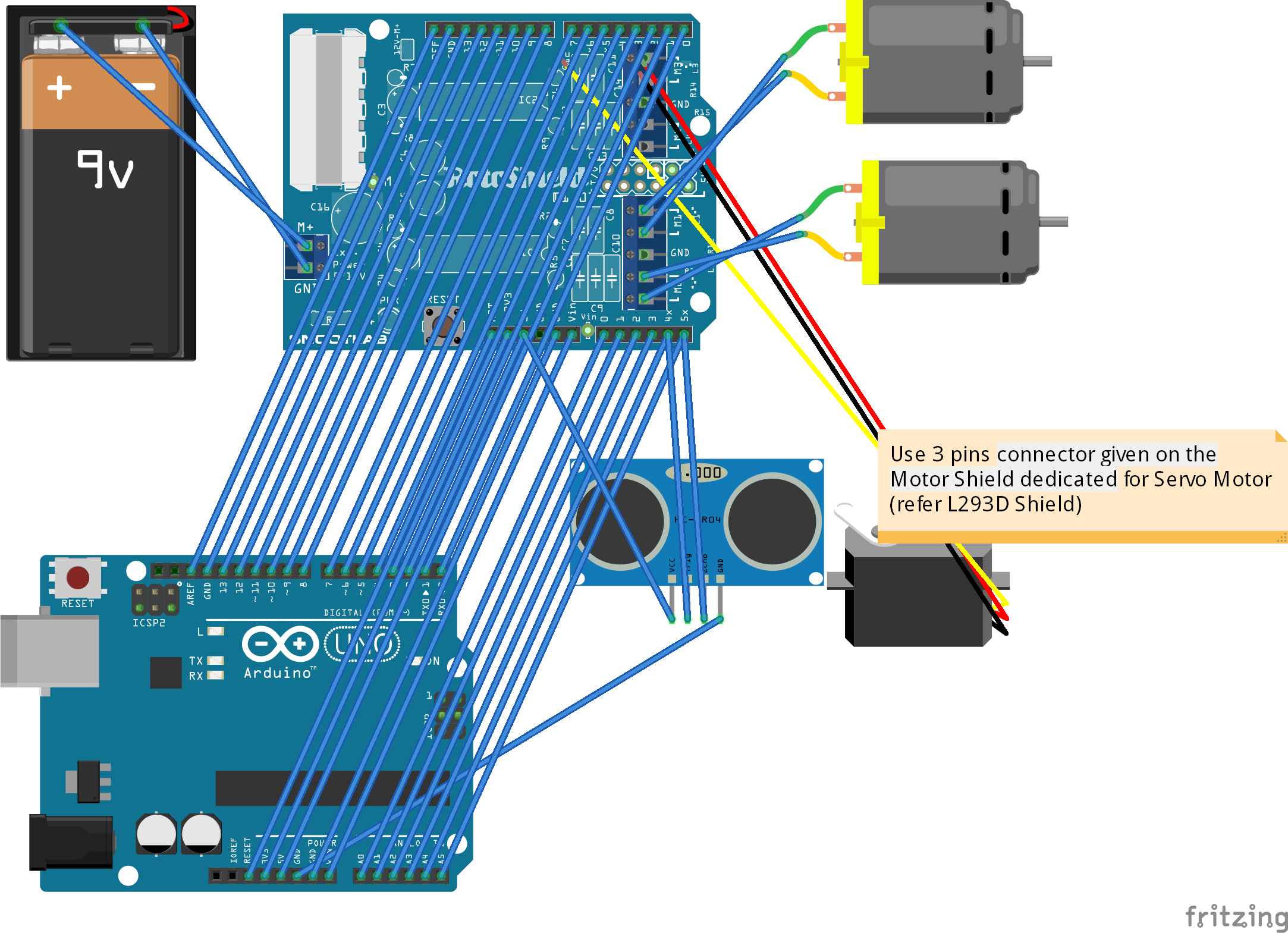

Furthermore, the L293D can also control one stepper motor. Stepper motors are special types of motors that move in discrete steps, making them ideal for precise positioning applications. A unipolar stepper motor can be controlled using one L293D because the L293D can control 4 coils to control stepper motor movement (with the right circuit). However, controlling bipolar stepper motors would need 2 H-bridges, each L293D will only be able to control 1 stepper motor at a time.

In essence, if you're willing to get creative and your motors' requirements are modest, you can potentially push the L293D beyond its "official" limit of two DC motors. But, always err on the side of caution. If in doubt, using a more powerful motor driver IC, or multiple L293Ds, is a safer and more reliable approach.

Voltage, Current, and That Pesky Heat

3. Respecting the Power Boundaries of the IC

We've touched on it briefly, but let's dive deeper into the voltage and current limitations of the L293D. These parameters are absolutely critical for ensuring the longevity and proper functioning of both the driver and your motors. Ignoring them is like ignoring the speed limit on a highway — you might get away with it for a while, but eventually, something bad will happen.

The maximum motor supply voltage (VCC2 or VS) for the L293D is 36V. This is the voltage that directly powers your motors. Going beyond this voltage will almost certainly damage the IC. The logic supply voltage (VCC1 or VSS) is typically 5V, and this powers the internal logic of the driver. These voltages must be within their specified ranges for proper operation. Double-check your motor datasheets and your power supply to ensure compatibility.

The continuous current per channel (output) is 600mA (0.6A). As mentioned before, this is the amount of current the L293D can safely provide to each motor continuously without overheating. The peak current is higher (around 1.2A), but this is only for very short bursts. Exceeding the continuous current for extended periods will cause the L293D to overheat, and eventually, it may fail permanently.

Heat is the enemy of electronics. When the L293D is operating near its current limits, it generates heat. Without proper heat sinking, this heat can build up and damage the IC. A small heatsink attached to the L293D can significantly improve its ability to dissipate heat. You can also improve airflow around the IC to help with cooling. If you're consistently pushing the L293D near its limits, consider using a more robust motor driver with better heat dissipation capabilities.

L293D Motor Driver IC Pinout, Datasheet And Specification, 43 OFF

Alternatives and Upgrades

4. Stepping Up Your Motor Control Game

Okay, let's face it: the L293D is a decent little workhorse, but it has its limitations. If you're working with larger, more power-hungry motors, or if you simply want more robust and reliable control, it's time to explore some alternatives. Fortunately, there's a whole world of motor driver ICs out there, each with its own strengths and weaknesses.

One popular upgrade option is the L298N. This is another dual H-bridge driver, but it can handle significantly higher voltages and currents than the L293D. It typically supports motor supply voltages up to 48V and continuous currents up to 2A per channel. This makes it suitable for a wider range of motors, including those used in larger robots and vehicles.

Another excellent choice is the TB6612FNG. This driver is known for its compact size and efficient operation. It can handle motor supply voltages up to 15V and continuous currents up to 1.2A per channel, with peak currents up to 3A. It also has built-in features like thermal shutdown and overcurrent protection, which can help prevent damage to the driver and your motors.

For more advanced applications, you might consider using dedicated motor driver modules. These modules often include additional features like current sensing, speed control, and fault detection. They're also typically easier to use than individual ICs, as they often come with pre-wired connectors and mounting holes. Examples include modules based on the DRV8825 and A4988 stepper motor driver chips, commonly used in 3D printers and CNC machines.

Frequently Asked Questions (FAQs)

5. Answering Your Burning Motor Control Questions

Let's tackle some common questions about the L293D and motor control in general.

Q: Can I use the L293D to control servo motors?A: No, servo motors require a different control signal (PWM) than the L293D provides for standard DC motors. Servo motors have their own built-in control circuitry.

Q: What happens if I exceed the current limit of the L293D?A: The L293D will overheat, and if the overcurrent condition persists, it will likely be damaged permanently. It might even let out a puff of smoke! Always ensure your motors' current draw is within the L293D's specifications.

Q: Can I use the L293D with a Raspberry Pi or Arduino?A: Absolutely! The L293D is commonly used with microcontrollers like the Raspberry Pi and Arduino. You'll need to connect the control pins of the L293D to digital output pins on your microcontroller to control the motors' direction and speed.

Q: Is it safe to run the L293D at its maximum voltage and current ratings continuously?A: While technically possible, it's generally not recommended. Operating the L293D near its maximum ratings will generate a lot of heat and potentially shorten its lifespan. It's always best to provide adequate heat sinking and keep the operating conditions well within the safe limits.