Looking Good Info About How Does PWM Motor Control Work

Decoding the Mystery of PWM Motor Control

1. What exactly is PWM, anyway?

Ever wondered how your fancy electric drill manages to go from a gentle purr to a high-speed whine without a complicated gear system? The answer, my friend, lies in the magic of Pulse Width Modulation, or PWM for short. Think of it as a sophisticated light dimmer for your motor, but instead of controlling brightness, it controls speed. Seriously, it's that neat!

Now, the phrase "Pulse Width Modulation" might sound intimidating, like something out of a sci-fi movie. But at its core, it's a brilliantly simple concept. Its all about quickly switching the power to the motor on and off. No, we aren't talking about manually flipping a light switch rapidly (that would be exhausting!). We're talking about using sophisticated electronics to perform this switching action thousands of times per second. So fast, in fact, that the motor doesn't even realize it's being turned on and off — it just perceives the average power delivered.

The secret sauce is in the "width" of the pulse. Imagine a light switch that is "on" for a certain amount of time and then "off" for a certain amount of time. The "pulse width" refers to the amount of time the switch is "on" during each cycle. By varying this width, we change the percentage of time the motor receives power. More "on" time means more power, and thus, higher speed. Less "on" time, well, you guessed it, means less power and lower speed. Its like giving your motor a series of tiny energy shots!

PWM motor control allows a small microcontroller to precisely control motor speed. It's efficient, reliable, and allows you to achieve a wide range of speeds from a single motor. You might even say that the variable speed power drill you use is a great PWM-controlled motor application. It is one example of how PWM controls make everyday products better.

DC Motor Speed Control PWM Circuit

The Nuts and Bolts

2. Delving into the Technical Details (But We'll Keep It Light)

Okay, let's dive a little deeper without getting lost in a sea of equations. Remember that rapid on/off switching we talked about? That's handled by a clever little electronic component often called a "switch" (creative, right?). This switch is controlled by a PWM signal generated by a microcontroller. The microcontroller is the brain of the operation. It's programmed to send a specific pattern of pulses to the switch, dictating how long it should be "on" and "off".

The key term here is "duty cycle." The duty cycle is the percentage of time the signal is "high" (on) compared to the total time of one cycle. A 50% duty cycle means the signal is "on" for half the time and "off" for the other half. A 90% duty cycle means it's "on" for almost the entire time. And so on. By adjusting the duty cycle, the microcontroller effectively fine-tunes the amount of power delivered to the motor. Think of it as a digital volume knob for your motor's speed!

The frequency of the PWM signal is also important. This refers to how many times the signal cycles between "on" and "off" per second. A higher frequency means smoother operation, as the motor experiences less noticeable "pulsing." Typically, PWM frequencies used in motor control are in the kilohertz range (thousands of cycles per second). This ensures that the switching is virtually imperceptible to the motor and the user.

Essentially, PWM converts a digital signal (the on/off pulses from the microcontroller) into an analog-like control over the motor's speed. By rapidly switching the power and varying the duty cycle, you can create a smooth, controllable speed range that goes beyond simply "on" or "off." It's like magic...powered by clever electronics!

24 Volt Dc Motor Pwm Control Circuit Diagram 6v To 24v Mo

Benefits of PWM Motor Control

3. More Than Just Speed Control

So, why is PWM motor control so widely used? Well, beyond the obvious benefit of variable speed, it offers a bunch of other advantages. For starters, it's incredibly efficient. Because the switch is either fully "on" or fully "off," it wastes very little energy. Think of it like a digital light switch versus an analog dimmer switch. The digital switch consumes no power when off, but an analog dimmer will consume power and generate heat. This contrasts with older methods of speed control that used resistors to dissipate excess energy as heat. PWM systems operate with much lower losses, saving energy and extending battery life (which is a huge plus for battery-powered devices).

Another benefit is the simplicity of the control circuitry. Modern microcontrollers have built-in PWM modules, making it easy to implement PWM motor control with minimal external components. This reduces the cost and complexity of the overall system. That is why you can find PWM controls in just about everything today. From a simple fan controller to a complicated surgical tool.

PWM also provides excellent torque control. By precisely controlling the amount of power delivered to the motor, you can maintain a consistent torque output even under varying loads. This is crucial for applications where precise control is essential, such as robotics or industrial automation.

Finally, PWM is incredibly versatile. It can be used to control a wide variety of motor types, including DC motors, stepper motors, and brushless DC (BLDC) motors. This adaptability makes it a powerful tool for engineers and designers across a wide range of industries.

PWM vs. Other Motor Control Methods

4. Is PWM Always the Best Choice? Let's Compare

While PWM is often the go-to method for motor control, it's not the only option. Let's take a quick look at how it stacks up against some other common techniques. One alternative is linear voltage control, where the motor voltage is directly varied using a potentiometer or other analog control. While this method is simple, it's also inefficient, as it wastes energy through resistive losses.

Another option is variable frequency drives (VFDs), which are typically used for controlling AC motors. VFDs adjust both the voltage and frequency of the AC power supplied to the motor, providing precise speed control. However, VFDs are more complex and expensive than PWM-based systems, making them better suited for high-power applications.

Finally, there's back-EMF control, which relies on measuring the back-electromotive force (EMF) generated by the motor as it rotates. This information is then used to adjust the motor's drive voltage and maintain a desired speed. Back-EMF control is often used in brushless DC (BLDC) motor applications.

PWM generally provides the best balance of simplicity, efficiency, and cost for a wide range of motor control applications. But the best choice for a specific application depends on the motor type, power requirements, and desired level of precision.

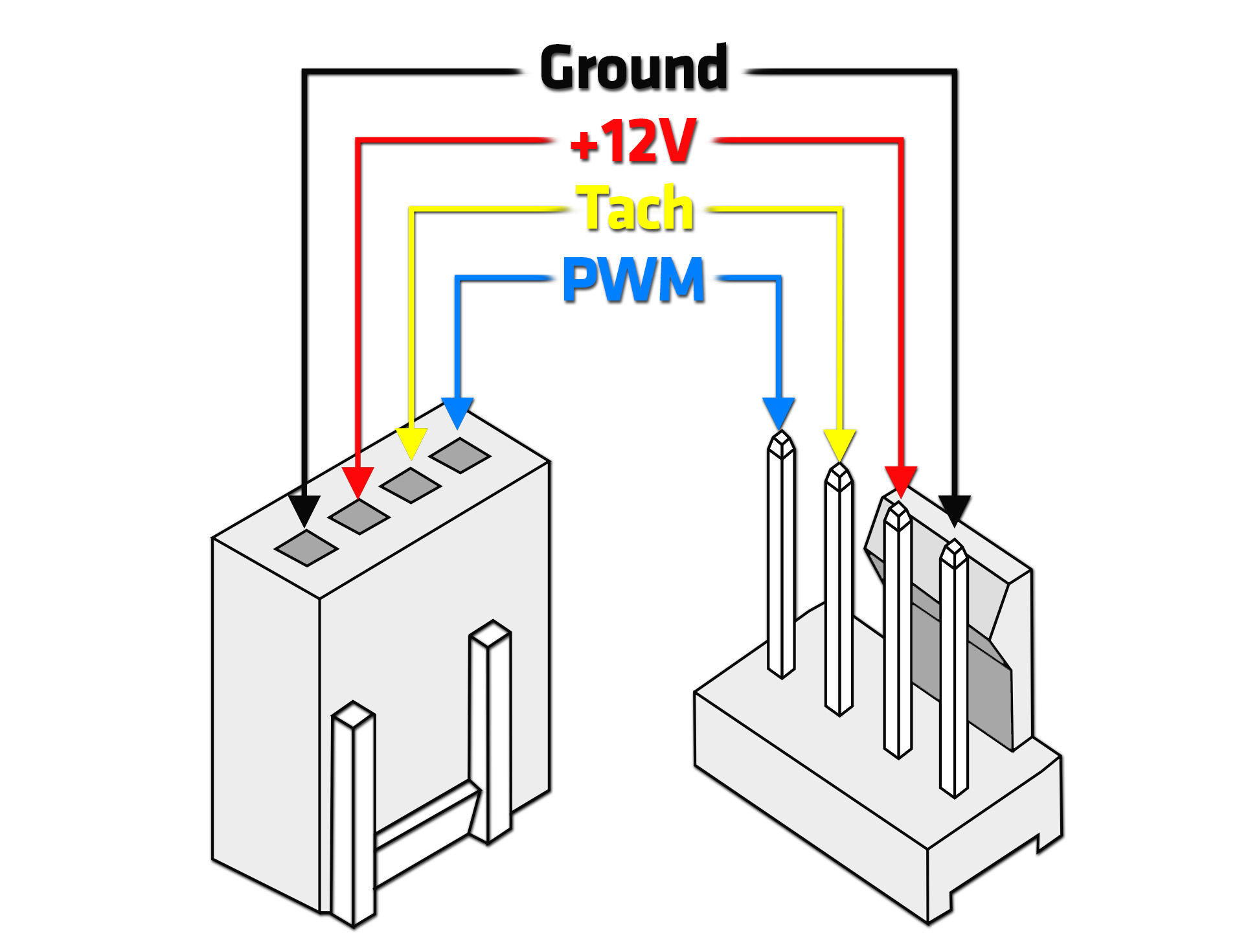

Diagram For Pwm Control Pines Ventilador Cpu Motherboard

Real-World Applications

5. From Toys to Tools

You might be surprised to learn just how many devices rely on PWM motor control. It's practically ubiquitous! Consider your household appliances. That variable-speed blender? Probably uses PWM. The electric fan with multiple speed settings? Almost certainly PWM. Your power drill? You guessed it — PWM is likely at play.

Beyond the home, PWM is used extensively in robotics, industrial automation, and automotive applications. Robots use PWM to precisely control the movements of their joints and manipulators. Industrial machinery relies on PWM for accurate speed and torque control. And in automobiles, PWM is used in everything from electric power steering to cooling fan control. It's basically the unsung hero of modern technology.

Even in the world of drones and radio-controlled (RC) vehicles, PWM is king. It allows for precise control of the motors that drive the propellers or wheels, enabling smooth and responsive handling. So, the next time you see a drone soaring through the sky, remember that PWM is working hard behind the scenes to keep it aloft.

Finally, consider medical devices. Many sophisticated medical instruments utilize PWM to accurately control motors for pumps, actuators, and other critical functions. The precision and reliability of PWM make it an ideal choice for these demanding applications.

PWM Troubleshooting

6. A Little Help When Your Motor Acts Up

Even with the best technology, things can sometimes go wrong. If you are experiencing problems with your PWM controlled motor, there are a few things to check. One of the most common issues is a faulty PWM signal. This could be due to a problem with the microcontroller, the wiring, or the motor driver IC. A multimeter or oscilloscope can be used to check the PWM signal to ensure that it is present and has the correct duty cycle and frequency.

Another potential issue is a problem with the motor itself. The motor could be damaged, worn out, or overloaded. If the motor is making unusual noises or is not spinning smoothly, it may need to be replaced. Additionally, check the motor's power supply to ensure it is providing the correct voltage and current. Insufficient power can cause the motor to perform erratically.

Overheating is another common problem, especially if the motor is running at a high duty cycle for extended periods. Make sure the motor has adequate ventilation and is not being overloaded. Consider using a heatsink or fan to dissipate heat. If the motor driver IC is overheating, it may indicate a short circuit or other problem with the motor or wiring.

Finally, check all connections and wiring for any loose or damaged connections. Poor connections can cause intermittent problems or complete failure. Ensure that all wires are properly connected and that there are no shorts or open circuits. Regular maintenance and careful troubleshooting can help keep your PWM controlled motor running smoothly for years to come.